Chemicals are the cause of more than 190,000 illnesses and 50,000 annual deaths. This is according to US annual estimates. Periods between chemical exposure and disease onset are long. So, these numbers are most likely underestimated. Employee illness and death costs businesses millions of dollars. Not only are hazardous chemicals a health detriment, but they are also a detriment to your bottom line.

Replace hazardous beer line cleaning chemicals with safer alternatives. This can help to decrease worker illnesses and deaths.

Beer line technicians may seem fine working with traditional beer line cleaning chemicals. But it is hard to determine the long-term effects of hazardous chemicals. Hazardous chemicals take a toll on the body and nervous system. Personal protective equipment (PPE) (masks, gloves and eye protection) are helpful. But, they’re only a shield.

It’s commonplace for beer line cleaners to have scabs and burns on their hands and forearms. This has become the norm. Unfortunately, many workers suffer severe burns that put them in the hospital. In the grand scheme of things, it is not worth the risk. There is risk to the worker and risk to the business owner.

We’re all aware of the physical, tangible injuries like burns. But hazardous chemicals can permeate the skin without sensory awareness. Chemicals affect the nervous system and other systems of the body like the immune system. Exposure to hazardous chemicals is a leading cause of nervous system illnesses. These include autoimmune diseases and other diseases that weaken the immune system.

“Thousands of workers still are becoming ill and dying as a result of exposure to hazardous chemical,” said Michaels, adding that workers are being “exposed to levels of chemicals that are legal, but not safe.” David Michaels, PhD

So, what’s the most effective way to end health and safety hazards in the workplace? How do you keep your employees safe? Eliminate at the source!

In other words, don’t waste your time with less effective alternatives. This is the “industrial hygiene principle.” It has been well-studied and accepted by industrial hygiene professionals and businesses worldwide.

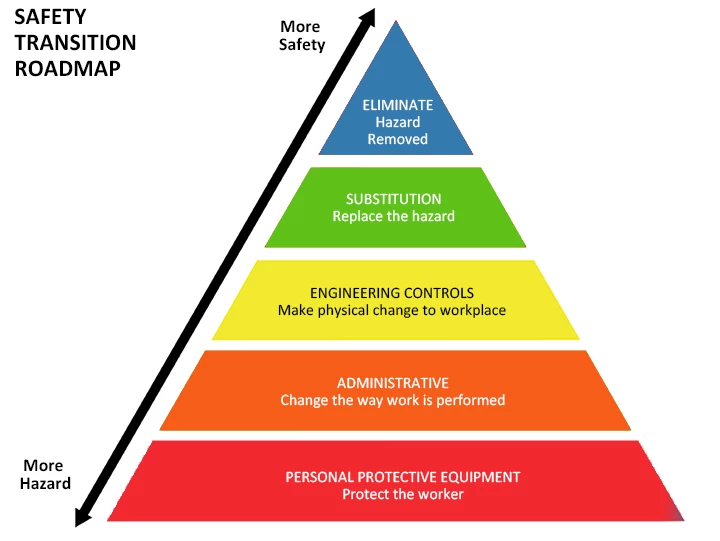

So how do you put this into action? The Safety Transition Roadmap is a step by step process to transition to safe chemicals. This guides employers and workers to reduce or completely omit hazardous chemicals.

The Safety Transition Roadmap reduces the potential for chemical accidents. It eliminates disposal costs. It also alleviates equipment maintenance and worker compliance concerns.

In the current climate of increasing costs of running a business, bottom line is key.

Using hazardous beer line cleaning chemicals creates liability costs in your business. Transition to safer chemicals to reduce these costs. The best part is, it’s a pretty uncomplicated changeover. Using safer chemicals can also reclassify your insurance category. This can bring great savings in annual insurance costs.

A 2008 study by the American Industrial Hygiene Association demonstrates another key point. Simple process improvements like transitioning to safe chemicals is a smart choice. This garners much greater savings than with other process change options. Complex controls like engineering or administrative and work practice controls are more costly.

Safecid Beer Line Cleaning chemicals are the way of the future. Keep your employees safe and reduce your liability and employee costs. Keep your company green as well. Safecid products are also safe and approved for groundwater release. Safecid produces acid and alkaline products for beer line cleaning and brewery cleaning.

Sources:

https://www.ncbi.nlm.nih.gov/pubmed/17317635

https://www.ncbi.nlm.nih.gov/pubmed/12505286

https://www.ehstoday.com/safety/article/21916568/osha-workers-are-not-being-protected-from-chemical-hazards

https://www.osha.gov

https://www.aiha.org/